"In our business, the customer normally provides the specifications for a product or we follow technology trends. Is QFD suitable for this type of industry and if so, how we go about it?"

Let us discuss the two scenarios presented here:

design to customer specification, and

redesign to technology trends

1. In designing to customer specification, QFD has been shown to help in many ways such as identifying the most critical customer needs out of a large list, and then deploying to Technology Mapping, Knowledge Management and Transfer, so forth.

For example, QFD can help you identify and fulfill the most critical customer specs "even when all you have to work with is a large specification document from an OEM (customer) describing a product they want you to make..." (“Using a Spec Document, the Customer Voice Table, and a QFD Matrix to Generate a Critical-to-Quality List” by Bruce White, Imation; 2006 Symposium on QFD).

The basic process steps outlined below is just one example of such QFD use.

QFD can be also used to document intrinsic engineering knowledge by visually mapping the contributions of technical capabilities to fulfilling customer needs. For example, Technology Mapping and QFD was a topic at the 2008 Symposium. In "Use of QFD & Technology Road Mapping to Develop a Mobile Data Collection System" by Dr. Kim Stansfield and Mr. Jeff Cole of CSC Computer Sciences, the authors described "how they systematically analyzed the requirements of the stakeholders for a mobile subsystem using SIPOC and QFD Analysis, and how the solution was identified using a Technology Road Map such that it met all of the requirements, and was different than the solution tentatively proposed by the customer.

The approach provided context to the design team and the senior customer management team, allowing the design team to proof in advance the first release of the system, and provided additional communication to all parties concerning the future growth of the system."

This naturally expands to the area of Knowledge Management which Dr. Akao has been proposing. QFD's intrinsic framework for Knowledge Management should be useful for companies expanding rapidly or needing to transfer the expertise of senior engineers to the younger generation of workers. The tools in QFD are versatile for any industry and excellent for documentation, organization, and communication of complex system ideas in a visually accessible form.

2. In designing to customer specification, has the customer ever specified wrong? While we say the customer is "king" it does not mean that we must only do as they say, because the customer will not be satisfied if we fulfill the incomplete or erroneous specification even if it came from them.

With QFD, we have the tools to translate the specification back to its underlying customer needs, and thus engage the customer into clarifying and improving their specifications, including validating a new concept and technology. For example, a presentation at the 2001 Symposium, "QFD Killed My Pet (Project) - Using QFD to Confirm Market Needs for New Technology" (Dwight Delgado, Fusion UV Systems, et. al.) described how the use of QFD saved the company from investing in an expensive new technology that the market was not ready to pay for, saving them millions of dollars.

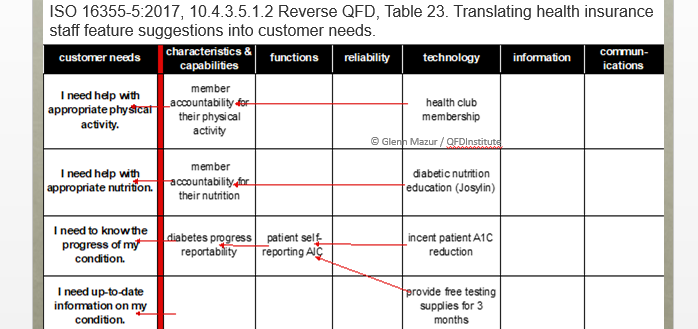

3. In redesigning to technology trends, we can use methods like Reverse QFD to better fine tune our product to unspoken customer needs.

Since the technology is pushing the design, there are going to be latent requirements that the customer does not know to specify or they assume so basic that its fulfillment is unspoken and expected (such as a working antenna when holding a cell phone). These requirements can easily change depending on the customer and his usage of yours, and his product.

The 2007 ISQFD presentation "Building Diversity: Using QFD to Involve Employees in the Corporate Innovation Process" by Kathy Hines, QFD Black Belt®, Blue Cross Blue Shield of Florida, et. al., stated: "QFD Technology Deployment is used to assure the quality of new technology concepts as they are being developed, and one variation of this is reverse QFD. In reverse QFD, concepts are generated internally and then mapped back into customer needs, which can then be prioritized by customers..."

Figure 1 diagram below illustrates the former: Reverse QFD flow chart by Kathy Hines, G. Mazur, et. al.

Another category of QFD benefit is to understand unspoken customer needs. When building to specification, it is often the case that most competitors try to compete on low price once they can meet the customer-provided spec. This should not be a long term strategy, however, because there will always be lower cost competitors emerging.

What creates product differentiation is to address exciting, unspoken needs that even the customer may not know can be addressed. This differentiation can lead to higher profits. QFD has the tools to examine what the customer specifies to uncover what he could not specify, but needs.

For example, by specification, an electronic component manufacturer who made linear amplifiers could not change the pin outs, the supplied voltage, the physical footprint, or the heat dissipation. However, by using QFD to examine the use of the product in which the linear amplifier was to be installed, we were able to add certain functions and parameters to the firmware of the amplifier, thus making the chip more suitable for its intended applications.

In another example, while implementing QFD with an automotive supplier, we uncovered the need for a more reliable pull-up resistor, but could not redesign the PCB to accommodate a higher wattage component. We then applied TRIZ (an innovation method that is now integrated into QFD) to come up with a solution that met both the reliability needs of the customer and the footprint needs of the PCB. This company also used QFD to improve their testing and validation process.

As OEMs look more to their supply chain for competitive differentiation, QFD provides specific tools and methods for suppliers and components manufacturers to:

Fulfill customer requirements beyond the stated needs and specification;

Identify what needs are most important to the end users and the areas that would give them unique advantage over competitors; and

Identify how to satisfy them with technical capabilities, while keeping in line with the project goals.

For questions, please contact us.