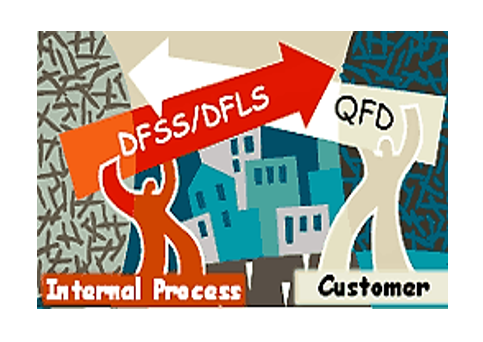

In recent weeks, we have had several opportunities to work with DFLS/DFSS (design for lean/six sigma) black belts and master black belts. We discovered something amazing: The focus of DFSS and DFLS is our internal products and processes, whereas the focus of QFD is our customers (especially, end users). One person suggested we rename QFD to DFCV (design for customer value).

Similarities

Both QFD and DFSS/DFLS want to improve product / service / software / process quality. How can we design and deliver more efficiently, more competitively, and create loyalty? Both look at how to develop solutions with high quality, low cost, and on-time. Both methods integrate other tools to improve the resulting products.

Differences

Focus.

DFSS/DFLS is product centric. The "define" stage in DMADV (one of the DFSS/DFLS algorithms) begins with a business case and a design concept. How does the product fit into the product portfolio, who else is making it, what are the technology trends, what is the product concept (what we want to deliver), what is the schedule and budget?

QFD is customer centric. What customers or segments do we want to acquire or retain, and why? What are those customers trying to do, when, where, how? What is their work or life process, where is it failing, frustrating, growing, enabling? What are their true needs, and which are most important? What are they doing now to address that need?

Customers.

DFSS/DFLS looks at today's customers and approaches them with surveys, focus groups, technology assessments. These marketing instruments are product-centric.A typical survey might ask: how did you find us, was our product available, was the price affordable, was the product easy to set-up or initiate use, were questions adequately answered, how often do you use the product, does the product work the way you expected, what other features would you like to see?

QFD looks at today's and tomorrow's customers and instructs us to approach them as explorers. We go to the "gemba" of the customer to see with our own eyes, hear with our own ears, and touch with our own hands, in order to understand how the customer works and lives. We pick up a shovel and help out; we look for customer anomalies and inefficiencies; not to blame them but to see how our products could be more effective. We listen to and observe customers to learn what goes smoothly in their jobs (so we don't inadvertently screw them up) and what goes poorly in their jobs (so we can make it smoother).

Afterwards, in QFD we ask questions about how customers measure their satisfaction (it is NEVER a simple 1-10 scale), what amount of satisfaction would it take to get them to change from what they currently doing to try something new, how important is one need relative to other needs?

VOC (Voice of Customer).

DFSS/DFLS takes the survey responses (which include a mixture of complaints, needs, solutions, and features) and treats them all as requirements to solve.

QFD takes gemba, survey, and other responses as raw data and translates them into true customer needs, which are benefits to the customer independent of the features. Customers have better knowledge about their needs than we do; this is what we want to learn more about. We have better knowledge about solutions and features than customers, so what can we learn by asking them?

Priority.

DFSS/DFLS looks at frequency and impact of a problem. Some MBBs recommend addressing the "low hanging fruit" first, because it is easiest.

QFD looks at priority of needs by having customers pair-compare them. This directs our first and best efforts to what matters most to customers. Solving what matters most may not be fastest or easiest (if it were, we would probably be doing it already), but it is where customers are most likely to get sufficient value to change from their current product to our new one.

Solutions.

DFSS/DFLS uses the House of Quality (HoQ) matrix to translate customer requirements and priorities into quality characteristics and priorities.

Depending on the complexity of the product, the HoQ matrix can grow to as large as 1000 rows x 1000 columns, creating 1,000,000 relationships to evaluate or test. While this may have worked well in Japan in the 1970s, it is rarely a tool for 21st century lean organizations. Some DFSS/DFLS MBBs say they hate doing QFD for this reason.

Modern Blitz QFD® precedes (and sometimes replaces) the House of Quality with a leaner tool - the Maximum Value table (MVT). Essentially, the MVT focuses efforts on the critical few needs that create customer value.

Design, Development, and Commercialization.

DFSS/DFLS still teaches the 1980s build-to-print approach of auto parts suppliers - the 4-matrix approach that deploys quality characteristics to component design parameters, process variables, and product processes. This approach assumes the customer provides a design that will satisfy their customers (ex: end users, consumers).

Modern Blitz QFD®'s MVT uses a single table to track all decisions from high level functional requirements through key systems, components, vendors, assemblies, implementation and build, testing, resources, support, packaging, logistics, commercialization, retirement, etc. Table size is controlled by focusing on the critical few customer needs. Matrices can be added when additional detail or discussion is useful.

Math.

DFSS/DFLS courses espouse six sigma accuracy (3ppm), but for many decisions, they still use ordinal scale math erroneously. These errors show up in prioritization matrices, FMEA RPN calculations, QFD charts, etc. The results have no mathematical meaning.

The QFD community replaced ordinal scale math with AHP as soon as PCs to do the calculations became available in the mid 1980s. AHP yields ratio scale priorities which properly support math functions like +, -, x, and /.

How can we get the best of both worlds?

It's not an either-or question. QFD can be described as a holistic approach that links business, customer, and technology in one end-to-end trackable flow with the goal of customer value — DFCV (Design For Customer Value).

QFD uses quantitative and non-quantitative tools to analyze the unknown unknowns, information that leads to sustainable competitiveness.

DFSS/DFLS provides a powerful set of statistical and analytic tools that can improve the efficiencies and effectiveness during the build of new products. QFD provides the umbrella of customer value as the driver and DFSS/DFLS kicks in downstream to assure that solutions are optimally developed.

We need them both!