"How do you address unspoken customer requirements?" asked someone in a Sigma forum.

Classical QFD as well as conventional Voice of Customer methods deal with the "spoken" needs, taking at the face value the customer verbatim gained from surveys, focus groups, and so forth.

In contrast, Modern QFD has specific tools for uncovering the "unspoken" needs and market opportunities beyond the stated obvious. This is why and how:

Requirements could reflect either customer needs or product requirements, so we should differentiate. Customer needs reflect benefits to the customer independent of the product. Product requirements describe functions and performance. Both needs and requirements can have stated and implied items. Satisfying implied needs is an opportunity for creativity; satisfying implied requirements is an opportunity for innovation.

A simple way to grasp this concept is to slightly rephrase these customer needs to "Customer buys products or service to solve their problems, enable their opportunities, and enhance their image." Be careful when customers give specifications; it means they are translating product requirements into needs in their minds, and they may get confused. Use the 5 Whys to get customers to explain why they want some function or performance.

Customer needs satisfaction is determined against customer measures, not product measures. Unfortunately, most satisfaction surveys only ask about product measures, thus yielding less powerful insight.

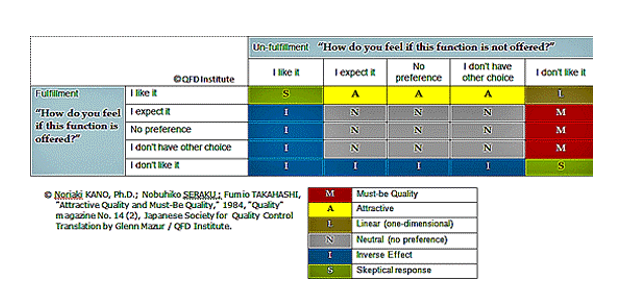

Quality is often characterized as "exciters," "desired," and "expected." The reference is from the 1984 research "Attractive Quality and Must-Be Quality" by Noriaki Kano, Ph.D., Nobuhiko Seraku, and Fumio Takahashi. Their original model (below) measured satisfaction against the existence or absence of a feature. It does NOT address customer needs, which are feature independent.

Additionally, the Kano categories are from survey responses by knowledgable customers responding to inverse-paired questions. They are NOT assigned by engineers.

A common error in interpreting Kano's response categories is the misleading curved-arrow diagram (as shown above and often cited by many). As the one who translated Dr. Kano's original Japanese paper into English for GOAL/QPC, I wonder if these people actually read his study.

The inverse-paired question yields only two data points: the "if" and the "if not". So, this means that you can only draw a line (= linear). It takes three (3) data points to inscribe a curve.

This problem was addressed by Mr. Harold Ross, a retired General Motors engineer and director of the QFD Institute. He called this the New Kano Model (below), and it adds the necessary questions to draw the curve and use it to extrapolate design decisions. It also reveals hidden market segments.

The answer really points to QFD, or Quality Function Deployment.

New Kano Model by Harold Ross. It addresses the missing link.

Another in the forum questioned the definition of QFD.

Let's get this right:

QFD means that the "quality function" must be "deployed" to all departments (including marketing, engineering, build, support, etc.) in order to satisfy customers in new product development. This is because the traditional role of the quality function comes too late in most organizations — right before production start-up.

QFD is specifically designed to translate customer needs into product functional requirements, performance specifications, concept innovation, reliability, cost, build, sourcing, inspection, support, retirement, etc.

Classical QFD began with a House of Quality (HoQ) matrix, which was then deployed to several additional houses (matrices) to compete the analysis. In the early 1980s, this original Comprehensive model of QFD by Dr. Yoji Akao was truncated into the so-called 4-House model. The truncation helped quick implementation by the U.S. auto part suppliers who were building to print at the time, but at the cost of limited applicability.

The classical model was modernized in the late 1990s by the U.S. experts, to better reflect non-automotive applications (service, software, etc.) operating in a Lean environment. The advantages of modern QFD come from developing an earlier focus on critical customer needs which must be the very foundation for successful product development. This has required brand new tools that were not available in the Classical QFD. These include the upgraded modern math.

Both Classical and Modern QFD tools and methods are being written into the new ISO 16355 standard for QFD. To learn more about both approaches, the correct way from the source, we invite you to join us in the next public courses (live online workshops).